This message is a reply to an archived post by rick872 on August 10, 2018 at 14:23:58.

The original subject was Re: Fairbanks Morse model 41.

5 years ago I posted about a Fairbanks Morse type 41 water pump. I have looked on and off for 5 years now finding almost no information and no parts but now it's time to get this cool old pump restored or at least working again. I have spent the week taking it apart and cleaning. I had no idea of just how bad of shape this pump is in. I struggle all day to just get one simple part removed. Today I removed the 1 1/2 plug in the front of the pump along with 3 pipe nipples. It took lots and lots of heat and a huge vise to hold it while a 6 foot cheater was on the wrench to get it to crack the almost welded together pipe thread. after several attempt and a good friend with a machine shop, we got it out!

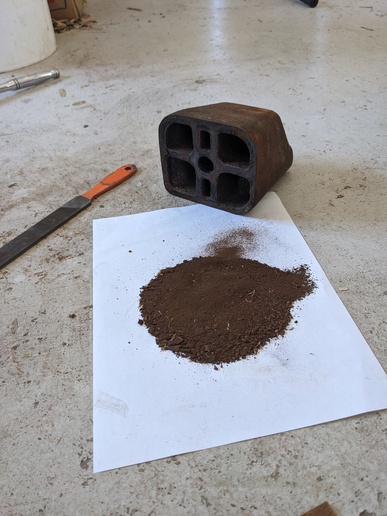

I am pleased to say that the bolt holding the top and bottom together came out without incidence. The inside valve plate is one lump of rust and calcium. I can hardly believe that it even worked at all.

good news is that it can be cleaned and repaired.

hopefully I can still contact rick872 about his experiences with his pump.

Thanks Rex

The original subject was Re: Fairbanks Morse model 41.

5 years ago I posted about a Fairbanks Morse type 41 water pump. I have looked on and off for 5 years now finding almost no information and no parts but now it's time to get this cool old pump restored or at least working again. I have spent the week taking it apart and cleaning. I had no idea of just how bad of shape this pump is in. I struggle all day to just get one simple part removed. Today I removed the 1 1/2 plug in the front of the pump along with 3 pipe nipples. It took lots and lots of heat and a huge vise to hold it while a 6 foot cheater was on the wrench to get it to crack the almost welded together pipe thread. after several attempt and a good friend with a machine shop, we got it out!

I am pleased to say that the bolt holding the top and bottom together came out without incidence. The inside valve plate is one lump of rust and calcium. I can hardly believe that it even worked at all.

good news is that it can be cleaned and repaired.

hopefully I can still contact rick872 about his experiences with his pump.

Thanks Rex