I have 1951 Ford 8N

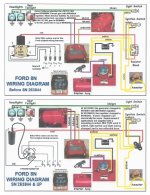

I changed it from 6volt system to 12 volt system. I put In an electronic ignition this worked fine for about 2 1/2 years.

I started it the other day and it ran for about 10 min while I was hooking up a blade on the back. Then it started sputtering died and wouldn't start again.

I checked for spark to plugs . There wasn't any. Instead of back tracking I assumed the the electronic ignition was bad. So I replaced it. Still no spark. Back tracked to coil . Power from ignition was there , no spark coming out. Replaced the coil. Still no spark. Wondered if it was the power wire from ignition. So replaced it. There is spark now to positive side of coil . Still nothing leaving coil to distributor.

Thought maybe ground were bad. In distributor. Took distributer out ,cleaned the base. Then pulled cap cleaned lightly sanded down beneath the electronic ignition Then rehooked up. Still no spark. Changed plug wires . No spark. The only thing I can figure the volts to ammeter , to ignition are messed up. Ballast was illuminated with 12 volt conversion. And coil is internally regulated.

How many volts , amps should be to the positive side of coil? Is my question.

Or am I not seeing the Forrest through the trees and missing something? Thank you soon much for helping if you can.

I changed it from 6volt system to 12 volt system. I put In an electronic ignition this worked fine for about 2 1/2 years.

I started it the other day and it ran for about 10 min while I was hooking up a blade on the back. Then it started sputtering died and wouldn't start again.

I checked for spark to plugs . There wasn't any. Instead of back tracking I assumed the the electronic ignition was bad. So I replaced it. Still no spark. Back tracked to coil . Power from ignition was there , no spark coming out. Replaced the coil. Still no spark. Wondered if it was the power wire from ignition. So replaced it. There is spark now to positive side of coil . Still nothing leaving coil to distributor.

Thought maybe ground were bad. In distributor. Took distributer out ,cleaned the base. Then pulled cap cleaned lightly sanded down beneath the electronic ignition Then rehooked up. Still no spark. Changed plug wires . No spark. The only thing I can figure the volts to ammeter , to ignition are messed up. Ballast was illuminated with 12 volt conversion. And coil is internally regulated.

How many volts , amps should be to the positive side of coil? Is my question.

Or am I not seeing the Forrest through the trees and missing something? Thank you soon much for helping if you can.