catalina0029

Member

I am new to this so pardon the stupid question.

I have a '64 4000 gas.The rear tires are brand new Firestone Traction Field & Road 13.6 x 28. The tire says not to exceed 35 psi when setting the bead. The specs on the web for the tire says 42 psi Max.

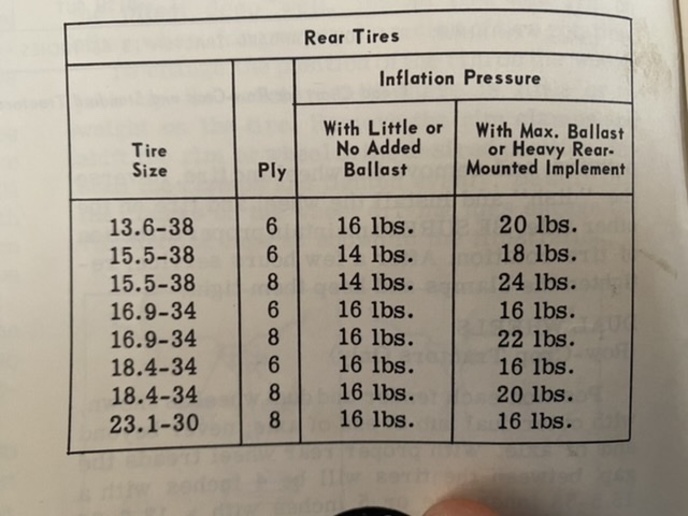

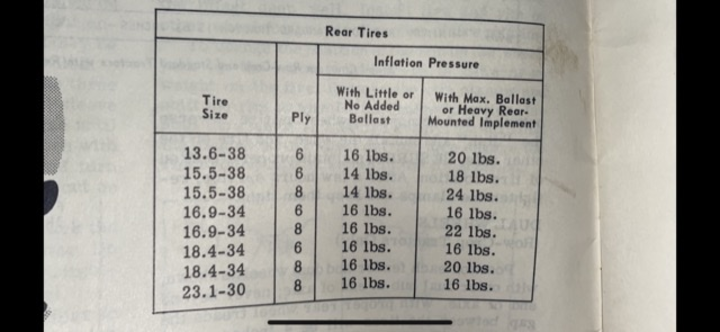

I've looked in the owners manual. I do not plan on filling the tires with liquid. What should I run for air pressure?

I plan on running a 5' brush cutter and a finish mower.

I have a '64 4000 gas.The rear tires are brand new Firestone Traction Field & Road 13.6 x 28. The tire says not to exceed 35 psi when setting the bead. The specs on the web for the tire says 42 psi Max.

Max Single Air Pressure(PSI) 42 The maximum air pressure this tire will support. This does not represent the amount of air pressure your tires should have at all times. Consult with your owner's manual to determine the best air pressure you should use for your vehicle.

I've looked in the owners manual. I do not plan on filling the tires with liquid. What should I run for air pressure?

I plan on running a 5' brush cutter and a finish mower.