I purchased a 1959 case 310 crawler with a bucket, ripper with counterweights. The original motor blew up and they put in a Chrysler flathead six cylinder. Haven’t ran the numbers yet on the Chrysler to figure out if it’s a 219 or 230 cu in ect. When the engine was put in they moved the hyd. Pump mount off the engine to the front cross member and made a drive shaft to run the hyd. pump.(pic#1 of my case 310 with mount for hyd. pump circled in red)

The question I have is could I use a pump off a later model case like a 310G?

With the inlet and outlet of the early hyd. Pump fit on the late model pump?

Would the late model pump inlet and outlet fittings will work with early hyd. Pump hyd hoses?

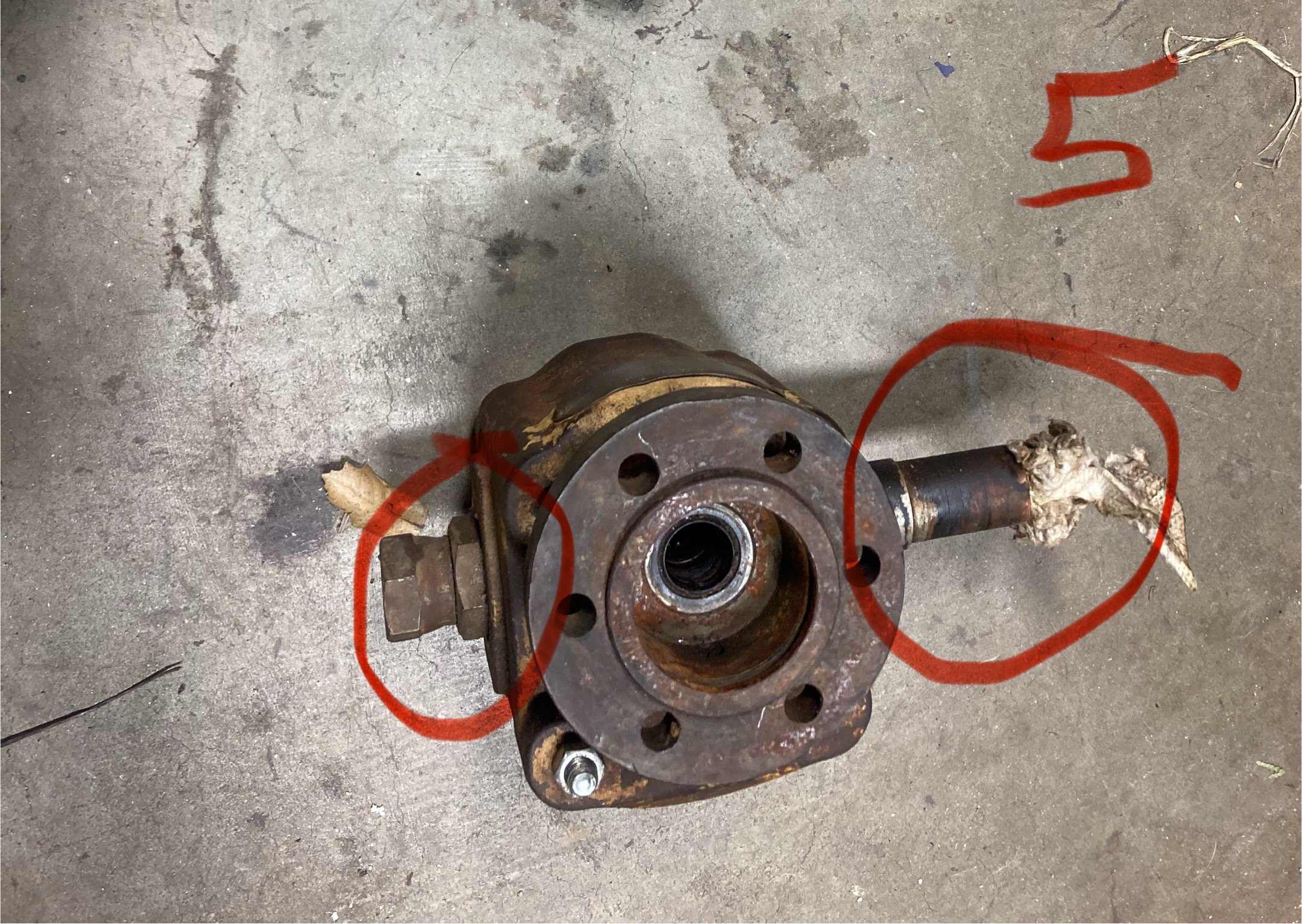

My plan is to put a late model hyd. pump from a 310G on my 310, ( pic #2 of replacement hyd pump),cut my drive shaft and weld a new coupler that will match my late model hyd pump spines (pic #3 old drive shaft red line where I will cut, pic #4 new coupler I will weld on) either attach the factory hoses if they will work with the new hyd. Pump or get new hoses made. Also can I use my early model pump hose inlet and out let fittings on the late model pump (pic #5 circle in red)

The question I have is could I use a pump off a later model case like a 310G?

With the inlet and outlet of the early hyd. Pump fit on the late model pump?

Would the late model pump inlet and outlet fittings will work with early hyd. Pump hyd hoses?

My plan is to put a late model hyd. pump from a 310G on my 310, ( pic #2 of replacement hyd pump),cut my drive shaft and weld a new coupler that will match my late model hyd pump spines (pic #3 old drive shaft red line where I will cut, pic #4 new coupler I will weld on) either attach the factory hoses if they will work with the new hyd. Pump or get new hoses made. Also can I use my early model pump hose inlet and out let fittings on the late model pump (pic #5 circle in red)